QT10-15 Automatic Hydraulic Block Making Machine

QT10-15 Automatic Hydraulic Block Making Machine

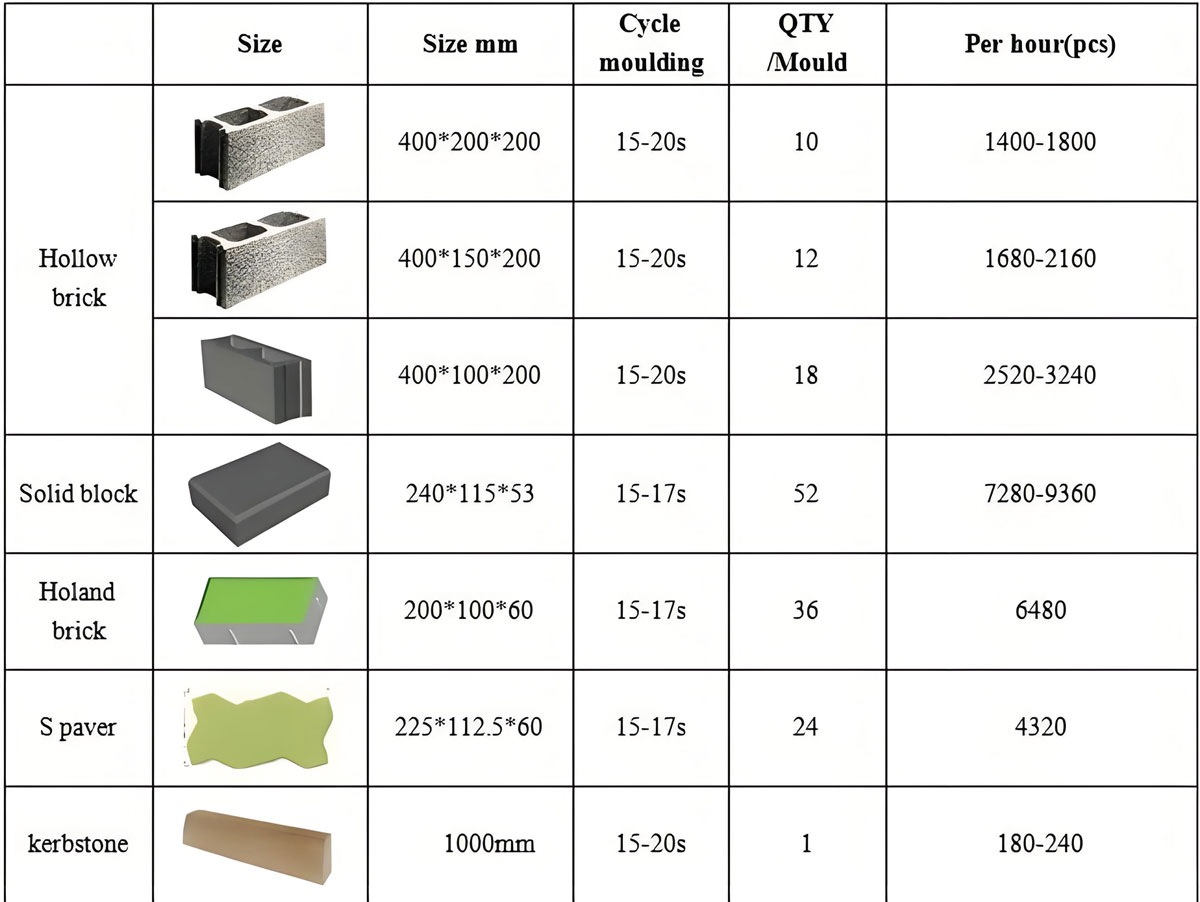

| Blocks can be produced: | Hollow/Solid/Paving Blocks, Kerbstone, etc. |

| Cycle Time: | 15-25s |

| Production Capacity (e.g.): | 400x200x200mm: 11200-14400pcs/day(8 hours) |

| 400x150x200mm: 13440-17280pcs/day(8 hours) | |

| 400x100x200mm: 20160-25920pcs/day(8 hours) | |

| Control Mode: | Automatic |

| Block Forming Mode: | Platform Vibration + Hydraulic Pressure |

E-mail: info@hongfa-industry.com

Tel/WhatsApp: +8616559783286

Product detail

QT10-15 Automatic Hydraulic Block Making Machine

Note: Block shapes and size can be customized

1. PLC intelligent control throughout the process, equipped with data input and output devices, to achieve the ideal man-machine dialogue. The control system also includes advanced safety logic control and fault diagnosis systems.

2. Adopt Mitsubishi color touch screen, hydraulic components are imported components. The high dynamic performance proportional valve can be used to adjust the oil volume according to different steps to precisely control the movement of key components.

3. The machine body adopts high-precision, high-strength section steel and special welding process technology, which is sturdy and resistant to vibration and has a long service life.

4. Mould frame movement adopts a rigid arm synchronous mechanism with four-bar guiding mode to ensure that the mould frame can rise smoothly and flexibly during demolding without causing damage to the forming brick machine. The body is made of super strong steel and special welding technology, which is strong and resistant to vibration.

5. The vibration box and the vibration table adopt an integrated structure and a universal shaft drive, which effectively avoids the connection between the table box and the damage caused by oil leakage and rigid joint transmission, and greatly improves the reliability of the vibration table.

6. Adopt special technology to optimize the arrangement of the vibration axis, so that the vibration is evenly distributed throughout the entire platen, thereby greatly improving the consistency of the performance of the blocks.

7. Adopt advanced hydraulic adjustable technology, which can easily regulate the pressure and oil volume of any branch oil circuit of the hydraulic system, so that various high-quality products can be produced using different raw materials.

8. The machine adopts table top vibration and pressure forming, and adopts a reciprocating forced feeding device. The forming cycle is short, the production efficiency is high, the block quality is dense, the strength is high, and the size is accurate.

9. Adopting the integrated technology of machinery, electricity and hydraulics, it is consistent in each cycle of the equipment operation, so the molded product has high stability and low rejection rate.

10. One machine is multi-purpose, and it can produce various specifications of porous bricks, hollow blocks, curbstones, pavement bricks, planting ring tree bricks, slope protection bricks and other cement products by changing different membrane tools.

11. The unique compulsory cloth mechanism and the special feeding rod that change with different mold cavities ensure the uniformity of the cloth with a large amount of fly ash.

12. Strictly follow the ISO9001 procedure to control each production process, fine processing guarantees the high precision of each component, and greatly improves the failure-free rate of the whole machine.

| No. | Item | Specification |

| 1 | Block Forming Mode | Platform Vibration + Hydraulic Pressure |

| 2 | Effective Forming Area | 1100 ×970 mm |

| 3 | Vibration Force | 680 kN |

| 4 | Vibration Frequency | 2800-4500 rpm |

| 5 | Rated Pressure | 21 Mpa |

| 6 | Production Cycle Time | 15-25 seconds |

| 7 | Main Motors Power | 43.3 kw |

| 8 | Pallet Size | 1100x950 mm |

| 9 | Main Machine Size | 9350×2320×2950 mm |

| 10 | Main Machine Weight | 10800 kg |

| 11 | Blocks can be produced | Hollow/Porous/Solid/Paving/Grass-planting Block, Kerbstone, etc. |

| High Strength Structural Steel

To produce our machines, we use high-strength structural steel. Steel rank can be Q345 – 16Mn.

|

Top Brands Parts

If some parts need to be ordered from others, we must choose top brands to keep quality. |

Production Equipment

We have more than 90 sets various production equipments, CNC machine tools, Plasma Cutting Machine and Flame Cutting, Machine, Wire-electrode Cutting Machine, Fully-automatic Milling Machine, Milling and Washing Machine, Polishing Machine, etc. to guarantee quality. |

| Designed workers

Different parts will be processed or manufactured by designed workers. If occur product defects, the designed workers should be responsible for it, even though machines have been delivered.

|

Welding

We have strictly welding demands. Welders must get National Welder Certificate. Welding lines should be uniform. Transition should be smooth.

|

Painting

Before painting, we must clean rust and oxide layer on the machines thoroughly. Then paint 4 layers. After above process, machines will be protected well from rust.

|

Copyright © 2025 Design by HONGFA INDUSTRY GROUP CO., LTD. All rights reserved.

Send Inquiry

Please leave the message you want to inquiry. We will reply you as soon as possible within 24 hours.