QT12-15 Automatic Hydraulic Block Making Machine

QT12-15 Automatic Hydraulic Block Making Machine

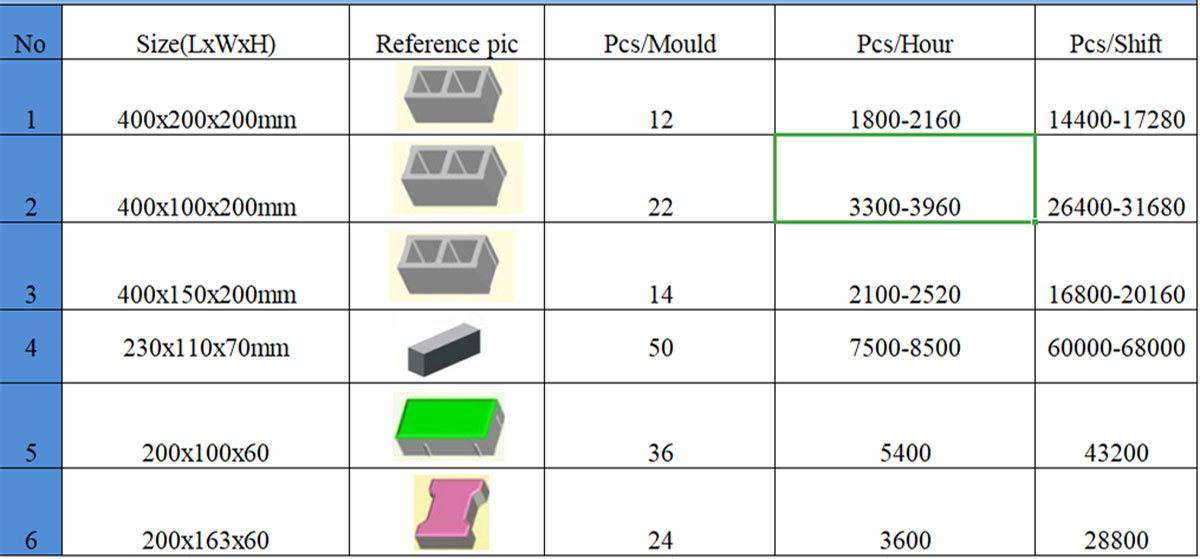

| Blocks can be produced: | Hollow/Solid/Paving Blocks, Kerbstone, etc. |

| Cycle Time: | 15-25s |

| Production Capacity (e.g.): | 400x200x200mm: 14400-17280pcs/day(8 hours) |

| 400x150x200mm: 16800-20160pcs/day(8 hours) | |

| 400x100x200mm: 26400-31680pcs/day(8 hours) | |

| Control Mode: | Automatic |

| Block Forming Mode: | Platform Vibration + Hydraulic Pressure |

E-mail: info@hongfa-industry.com

Tel/WhatsApp: +8616559783286

Product detail

QT12-15 Automatic Hydraulic Block Making Machine

Note: Block shapes and size can be customized

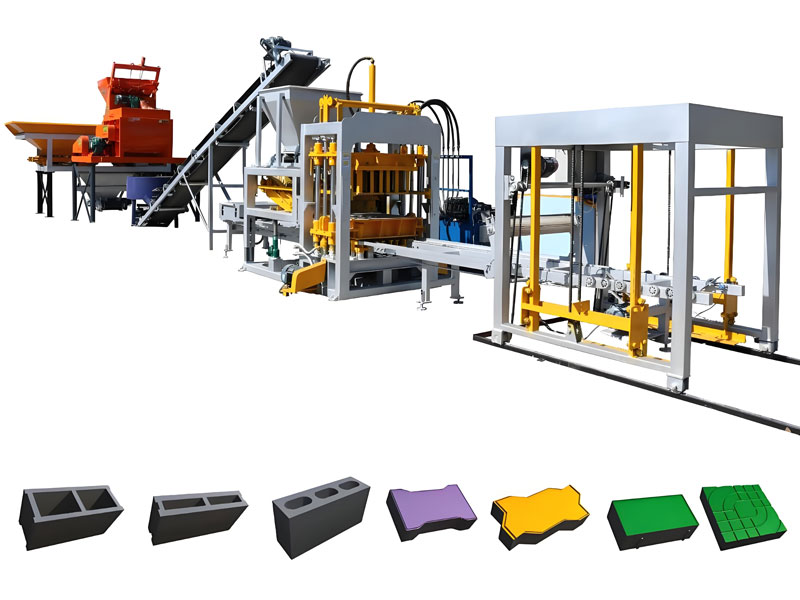

The QT12-15 block forming machine utilizes a tabletop vibrating pressurized molding process, reciprocating forced material distribution, oil-driven operation, and full computer control.

Based on customer needs and the raw materials used, the QT12-15 block forming machine can be combined with an SN100 cement silo, PL1200 batching machine, JS750 forced twin-shaft mixer, 8-meter belt conveyor, plate feeder, brick feeder, and 12-15 plate stacking machines to create various simple block production lines. (Users provide their own pallets, ZL40 loader, and forklift.) Large-scale production can be performed by just 6-8 people.

| No. | Item | Specification |

| 1 | Block Forming Mode | Platform Vibration + Hydraulic Pressure |

| 2 | Effective Forming Area | 1300 ×970 mm |

| 3 | Vibration Force | 680 kN |

| 4 | Vibration Frequency | 2800-4500 rpm |

| 5 | Rated Pressure | 21 Mpa |

| 6 | Production Cycle Time | 15-25 seconds |

| 7 | Main Motors Power | 50.7 kw |

| 8 | Pallet Size | 1300x950 mm |

| 9 | Main Machine Size | 9350×2320×2950 mm |

| 10 | Main Machine Weight | 14500 kg |

| 11 | Blocks can be produced | Hollow/Porous/Solid/Paving/Grass-planting Block, Kerbstone, etc. |

| High Strength Structural Steel

To produce our machines, we use high-strength structural steel. Steel rank can be Q345 – 16Mn.

|

Top Brands Parts

If some parts need to be ordered from others, we must choose top brands to keep quality. |

Production Equipment

We have more than 90 sets various production equipments, CNC machine tools, Plasma Cutting Machine and Flame Cutting, Machine, Wire-electrode Cutting Machine, Fully-automatic Milling Machine, Milling and Washing Machine, Polishing Machine, etc. to guarantee quality. |

| Designed workers

Different parts will be processed or manufactured by designed workers. If occur product defects, the designed workers should be responsible for it, even though machines have been delivered.

|

Welding

We have strictly welding demands. Welders must get National Welder Certificate. Welding lines should be uniform. Transition should be smooth.

|

Painting

Before painting, we must clean rust and oxide layer on the machines thoroughly. Then paint 4 layers. After above process, machines will be protected well from rust.

|

Copyright © 2025 Design by HONGFA INDUSTRY GROUP CO., LTD. All rights reserved.

Send Inquiry

Please leave the message you want to inquiry. We will reply you as soon as possible within 24 hours.