QT4-15 Automatic Hydraulic Block Making Machine

QT4-15 Automatic Hydraulic Block Making Machine

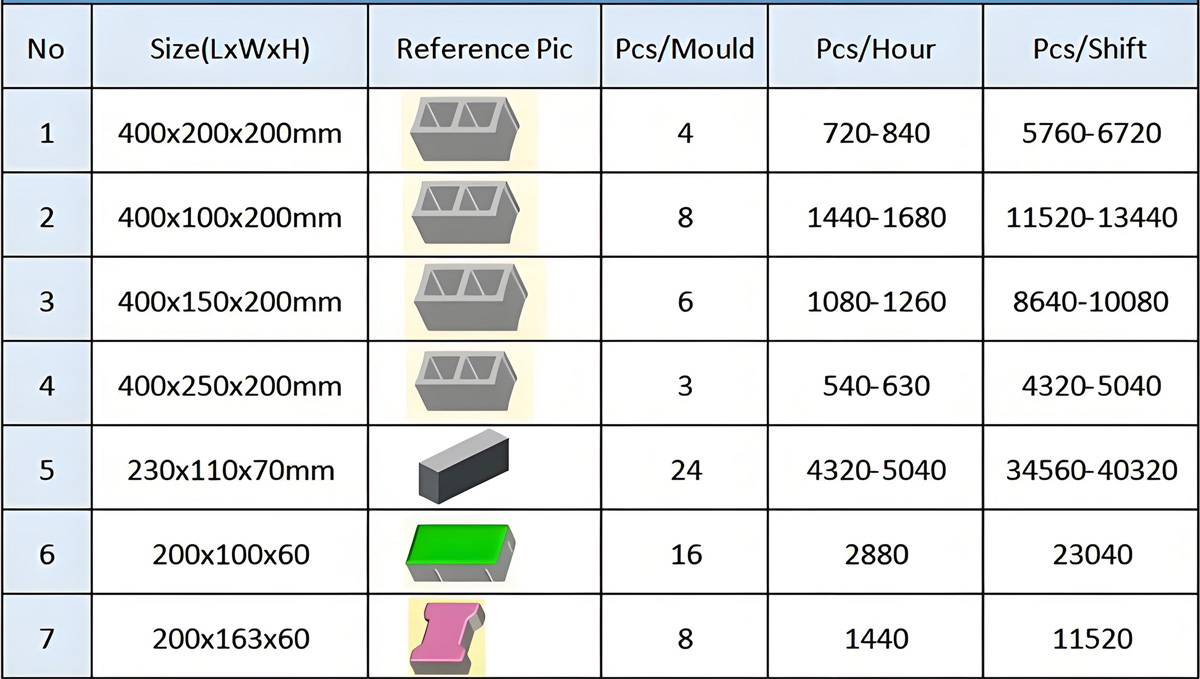

| Blocks can be produced: | Hollow/Solid/Paving Blocks, Kerbstone, etc. |

| Cycle Time: | 15-25s |

| Production Capacity (e.g.): | 400x200x200mm: 5760-6720pcs/day(8 hours) |

| 400x150x200mm: 8640-10080pcs/day(8 hours) | |

| 400x100x200mm: 11520-13440pcs/day(8 hours) | |

| Block Forming Mode: | Platform Vibration + Hydraulic Pressure |

| Control Mode: | Automatic |

E-mail: info@hongfa-industry.com

Tel/WhatsApp: +8616559783286

Product detail

QT4-15 Automatic Hydraulic Block Making Machine

Note: Block shapes and size can be customized

The QT4-15 block forming machine is a fully automatic, programmable block forming machine with the following features:

1. It offers versatile functionality and adaptability. It can utilize a wide range of materials, including fly ash, slag, gangue, or other industrial waste, as well as sand, stone, and cement. By changing molds, it can produce hollow blocks of various specifications, as well as various types of paving bricks, grass bricks, curbstones, and standard bricks. Fly ash usage can reach up to 70%.

2. The entire production process is controlled by a PLC, driven by a hydraulic system, and monitored by contactless proximity switches. Integrating mechanical, electrical, optical, hydraulic, and high-frequency vibration technologies, the machine automates plate feeding, material distribution, pressure vibration, demolding, and brick discharging. This ensures continuous and reliable operation, high production efficiency, and minimal operator workload. It is also durable and easy to maintain.

3. The machine's main electrical and hydraulic components are all imported or domestically produced, resulting in minimal malfunctions, reliable performance, durability, and easy maintenance.

4. Block forming is primarily hydraulic, supplemented by mechanical, and completed with vibration pressurization. The equipment is equipped with our company's patented vibration box, which provides high excitation force and frequency.

5. The organic combination of vibration and pressure makes the products more durable. The blocks produced achieve a tensile strength exceeding 15 MPa, high density, excellent frost and impermeability resistance, superior sound insulation, heat insulation, and thermal insulation, and precise dimensions.

6. The forced synchronous mold lifting mechanism ensures consistent product thickness, smooth demolding, and a high yield rate.

7. One-time, rapid, integrated demolding enables centralized handling and palletizing, improving production efficiency, reducing power consumption, and conserving human resources.

| No. | Item | Specification |

| 1 | Block Forming Mode | Platform Vibration + Hydraulic Pressure |

| 2 | Vibration Force | 380 kN |

| 3 | Vibration Frequency | 4600 rpm |

| 4 | Rated Pressure | 16 Mpa |

| 5 | Production Cycle Time | 15-20 seconds |

| 6 | Main Motors Power | 28 kw |

| 7 | Pallet Size | 1020x570 mm |

| 8 | Main Machine Size | 7100x1600x2610 mm |

| 9 | Main Machine Weight | 4500 kg |

| 10 | Blocks can be produced | Hollow/Porous/Solid/Paving/Grass-planting Block, Kerbstone, etc. |

| High Strength Structural Steel

To produce our machines, we use high-strength structural steel. Steel rank can be Q345 – 16Mn.

|

Top Brands Parts

If some parts need to be ordered from others, we must choose top brands to keep quality. |

Production Equipment

We have more than 90 sets various production equipments, CNC machine tools, Plasma Cutting Machine and Flame Cutting, Machine, Wire-electrode Cutting Machine, Fully-automatic Milling Machine, Milling and Washing Machine, Polishing Machine, etc. to guarantee quality. |

| Designed workers

Different parts will be processed or manufactured by designed workers. If occur product defects, the designed workers should be responsible for it, even though machines have been delivered.

|

Welding

We have strictly welding demands. Welders must get National Welder Certificate. Welding lines should be uniform. Transition should be smooth.

|

Painting

Before painting, we must clean rust and oxide layer on the machines thoroughly. Then paint 4 layers. After above process, machines will be protected well from rust.

|

Copyright © 2025 Design by HONGFA INDUSTRY GROUP CO., LTD. All rights reserved.

Send Inquiry

Please leave the message you want to inquiry. We will reply you as soon as possible within 24 hours.