QT6-15 Automatic Hydraulic Block Making Machine

QT6-15 Automatic Hydraulic Block Making Machine

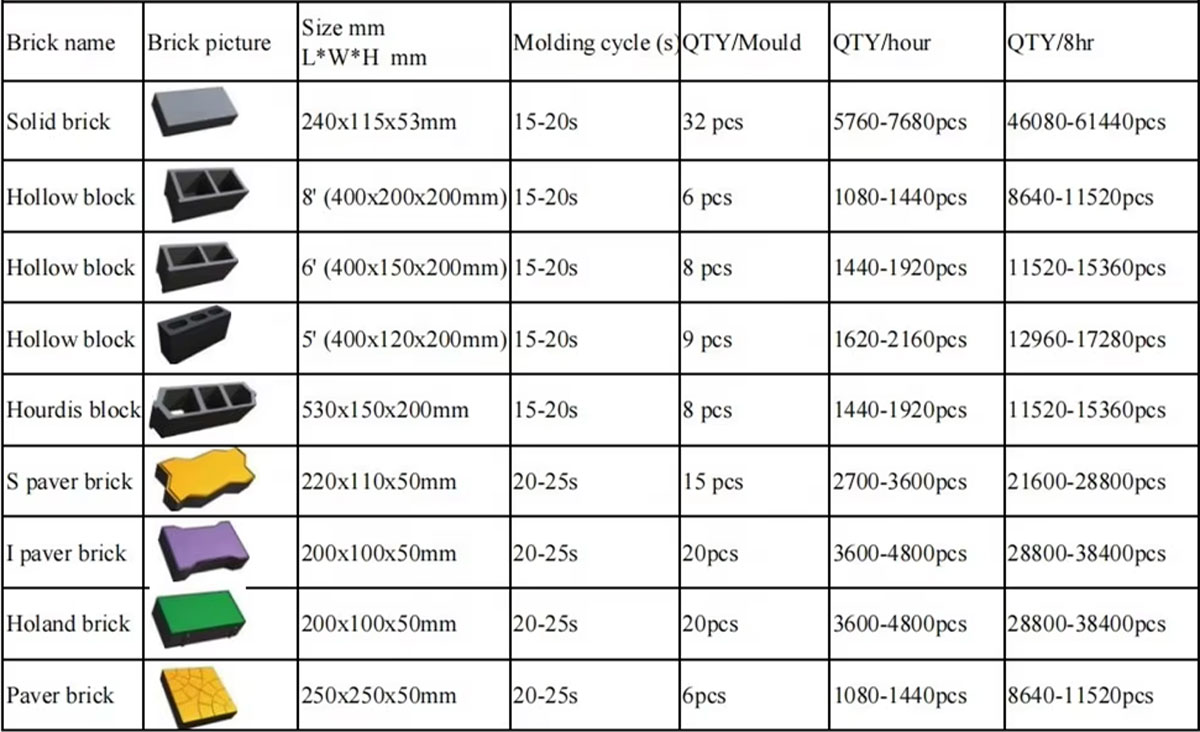

| Blocks can be produced: | Hollow/Solid/Paving Blocks, Kerbstone, etc. |

| Cycle Time: | 15-25s |

| Production Capacity (e.g.): | 400x200x200mm: 8640-11520pcs/day(8 hours) |

| 400x150x200mm: 11520-15360pcs/day(8 hours) | |

| 400x100x200mm: 12960-17280pcs/day(8 hours) | |

| Control Mode: | Automatic |

| Block Forming Mode: | Platform Vibration + Hydraulic Pressure |

E-mail: info@hongfa-industry.com

Tel/WhatsApp: +8616559783286

Product detail

QT6-15 Automatic Hydraulic Block Making Machine

Note: Block shapes and size can be customized

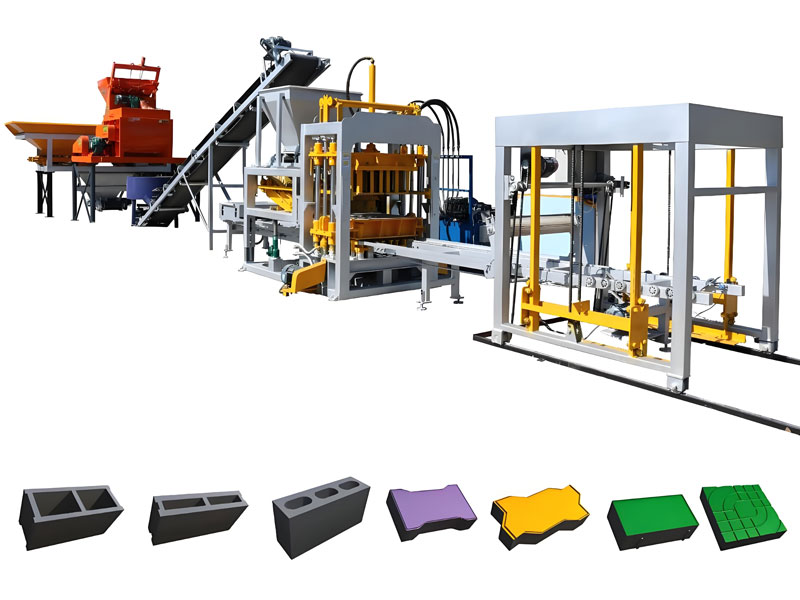

QT6-15 block making machine, is a special-purpose equipment for making building blocks. The material of this machine can be flyash, slag, gangue or the others industrial waste, river sand, gravel, cement etc. Makes different sizes of hollow blocks, porous blocks, curbstone, pavement blocks, grass blocks, slope-protecting blocks, ring-tree blocks etc. If add color machine, it can make layering blocks.

This equipment is mechanical hydraulic PLC controlled synthesis technique equipment. Its characteristic is high efficient, easy-operated and easy-maintained. Block molding mainly by hydraulic, machinery as sideline, vibrate and press to finish molding blocks. The compressive strength of all blocks more than 15MPa, compactness is high, impermeability and freeze resistance is better, and excellent capacity of sound insulation, heat insulation, insulation.external dimensions are precise, the blocks are more consistency, low waster rate.

| No. | Item | Specification |

| 1 | Block Forming Mode | Platform Vibration + Hydraulic Pressure |

| 2 | Effective Forming Area | 880 ×750 mm |

| 3 | Vibration Force | 380 Kn |

| 4 | Vibration Frequency | 4500-5100 rpm |

| 5 | Rated Pressure | 16 Mpa |

| 6 | Production Cycle Time | 15-25 seconds |

| 7 | Main Motors Power | 31.95 kw |

| 8 | Pallet Size | 850x680 mm |

| 9 | Main Machine Size | 7100x1500x3000 mm |

| 10 | Main Machine Weight | 6200 kg |

| 11 | Blocks can be produced | Hollow/Porous/Solid/Paving/Grass-planting Block, Kerbstone, etc. |

| High Strength Structural Steel

To produce our machines, we use high-strength structural steel. Steel rank can be Q345 – 16Mn.

|

Top Brands Parts

If some parts need to be ordered from others, we must choose top brands to keep quality. |

Production Equipment

We have more than 90 sets various production equipments, CNC machine tools, Plasma Cutting Machine and Flame Cutting, Machine, Wire-electrode Cutting Machine, Fully-automatic Milling Machine, Milling and Washing Machine, Polishing Machine, etc. to guarantee quality. |

| Designed workers

Different parts will be processed or manufactured by designed workers. If occur product defects, the designed workers should be responsible for it, even though machines have been delivered.

|

Welding

We have strictly welding demands. Welders must get National Welder Certificate. Welding lines should be uniform. Transition should be smooth.

|

Painting

Before painting, we must clean rust and oxide layer on the machines thoroughly. Then paint 4 layers. After above process, machines will be protected well from rust.

|

Copyright © 2025 Design by HONGFA INDUSTRY GROUP CO., LTD. All rights reserved.

Send Inquiry

Please leave the message you want to inquiry. We will reply you as soon as possible within 24 hours.