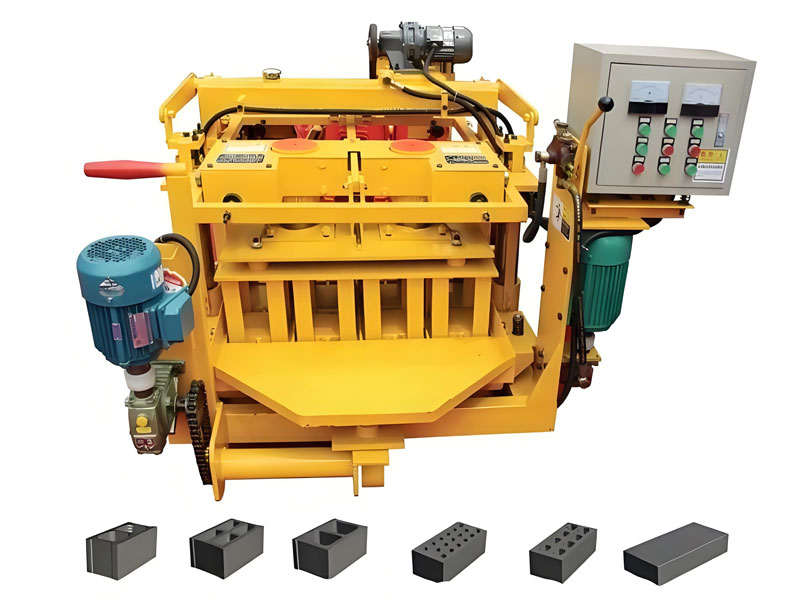

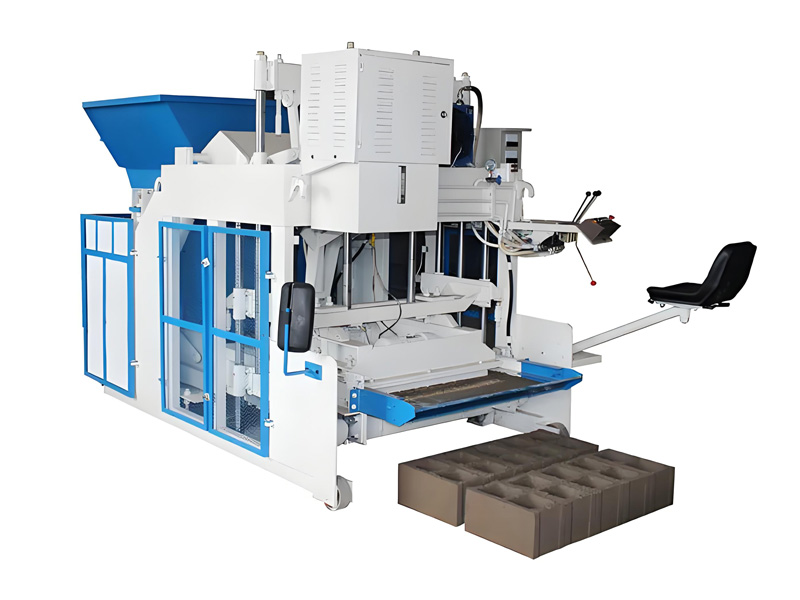

JMQ-6A Egg Laying Block Making Machine

JMQ-6A Egg Laying Block Making Machine

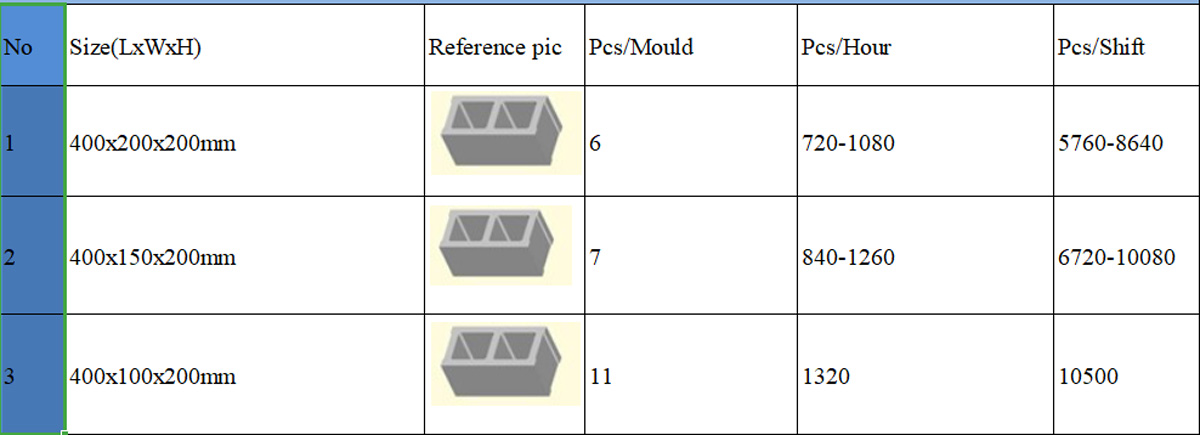

| Blocks can be produced: | Hollow/Solid/Paving Blocks, Kerbstone, etc. |

| Cycle Time: | 20-30s |

| Production Capacity (e.g.): | 400x200x200mm: 5760-8640pcs/day(8 hours) |

| 400x150x200mm: 6720-10080pcs/day(8 hours) | |

| 400x100x200mm: 10500pcs/day(8 hours) | |

| Block Forming Mode: | Vibration + Pressure |

E-mail: info@hongfa-industry.com

Tel/WhatsApp: +8616559783286

Product detail

JMQ-6A Egg Laying Block Making Machine

Note: Block shapes and size can be customized

The whole design process consider principle of integrative reconciliation and the internal structure of a rational order, so the machine have great technical advantage, it adopt several new technique, such as box excitation, hydraulic discharge, omnidirectional automatically movement.

High quality: the whole machine is adopted high quality steel, and precision welding, the hydraulic system use high-quality components, so it have a longer life and less fault during work.

Low investment: high efficiency: this machine have several function features, such as low price, reliable performance, easy to operated, stable, more efficient, high output, low power consumption. The brick it produced have high density, high strength, accurate dimensional, good appearance, so it can reduce the customer's investment and production costs and give fast and large benefit.

Heavy duty machine structure and wear resistant moulds are processed with carburizing, nitriding, wolfram carbide and quenching which ensures its strength reach to 54~58 HRC and can be used 100 thousand times. Greatly improves the using lifetime of the machine by 50%.

Use Frequency Conversional Control Technology, which controls the block making:

1. Frequency Conversion Control: guarantees the precise and parallel movement between tamper head and mould, protects the products

from transfiguration; increases the production rate by improving the vibrating efficiency;

2. Controls the instantaneous start and stop of the motors, to protect the motor from over-heating caused by constant working;

3. Power saving: 30%.

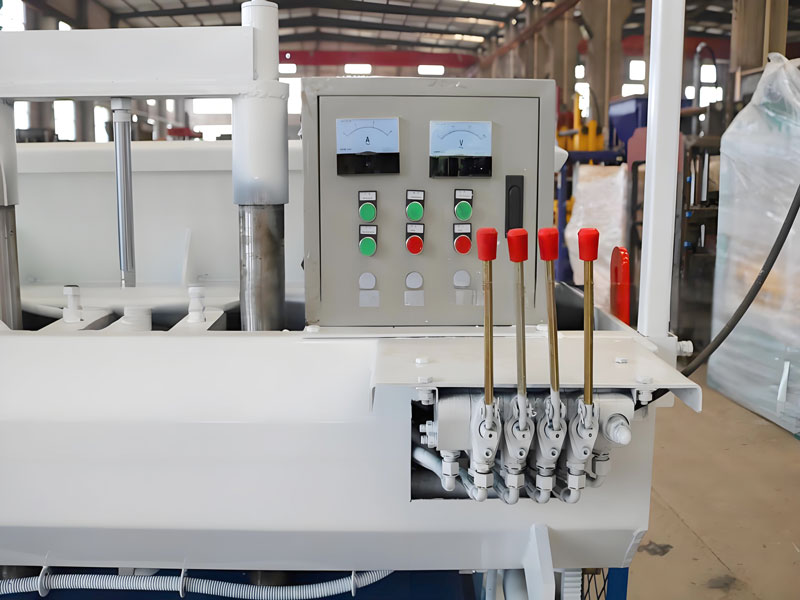

Use Double high-dynamic Proportional/Directional Valves to automatically adjust the oil flow and pressure

1.Buffer the hydraulic cylinder, to protect the cylinder from damage caused by inertia;

2.Guarantee production stability.

360° Multi-Shaft Rotating and Compulsory Feeding:

1. Speedy and rotating feeding, with uniform mixing, to make sure that the density and intensity of the products are guaranteed;

2. This uniform feeding is applicable for different kinds of raw materials and moulds.

| No. | Item | Specification |

| 1 | Block Forming Mode | Vibration + Pressure |

| 2 | Demoulding Method | Hydraulic |

| 3 | Turning Method | Hydraulic |

| 4 | Hydraulic Pressure | 6-8 Mpa |

| 5 | Vibration Form | Mould Vibration |

| 6 | Vibration Frequency | 3500 rpm |

| 7 | Production Cycle Time | 30 seconds |

| 8 | Main Motors Power | 9.6 kw |

| 9 | Pallet Size | No need pallet |

| 10 | Weight | 2600 kg |

| 11 | Blocks can be produced | Hollow/Porous/Paving/Solid Block, Kerbstone, etc. |

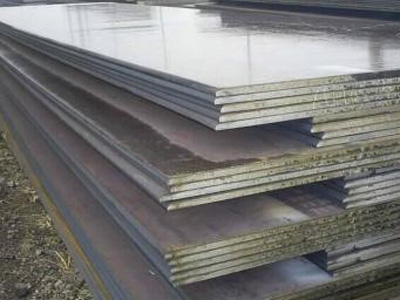

| High Strength Structural Steel

To produce our machines, we use high-strength structural steel. Steel rank can be Q345 – 16Mn.

|

Top Brands Parts

If some parts need to be ordered from others, we must choose top brands to keep quality. |

Production Equipment

We have more than 90 sets various production equipments, CNC machine tools, Plasma Cutting Machine and Flame Cutting, Machine, Wire-electrode Cutting Machine, Fully-automatic Milling Machine, Milling and Washing Machine, Polishing Machine, etc. to guarantee quality. |

| Designed workers

Different parts will be processed or manufactured by designed workers. If occur product defects, the designed workers should be responsible for it, even though machines have been delivered.

|

Welding

We have strictly welding demands. Welders must get National Welder Certificate. Welding lines should be uniform. Transition should be smooth.

|

Painting

Before painting, we must clean rust and oxide layer on the machines thoroughly. Then paint 4 layers. After above process, machines will be protected well from rust.

|

Copyright © 2025 Design by HONGFA INDUSTRY GROUP CO., LTD. All rights reserved.

Send Inquiry

Please leave the message you want to inquiry. We will reply you as soon as possible within 24 hours.